Resources

Resources

resources

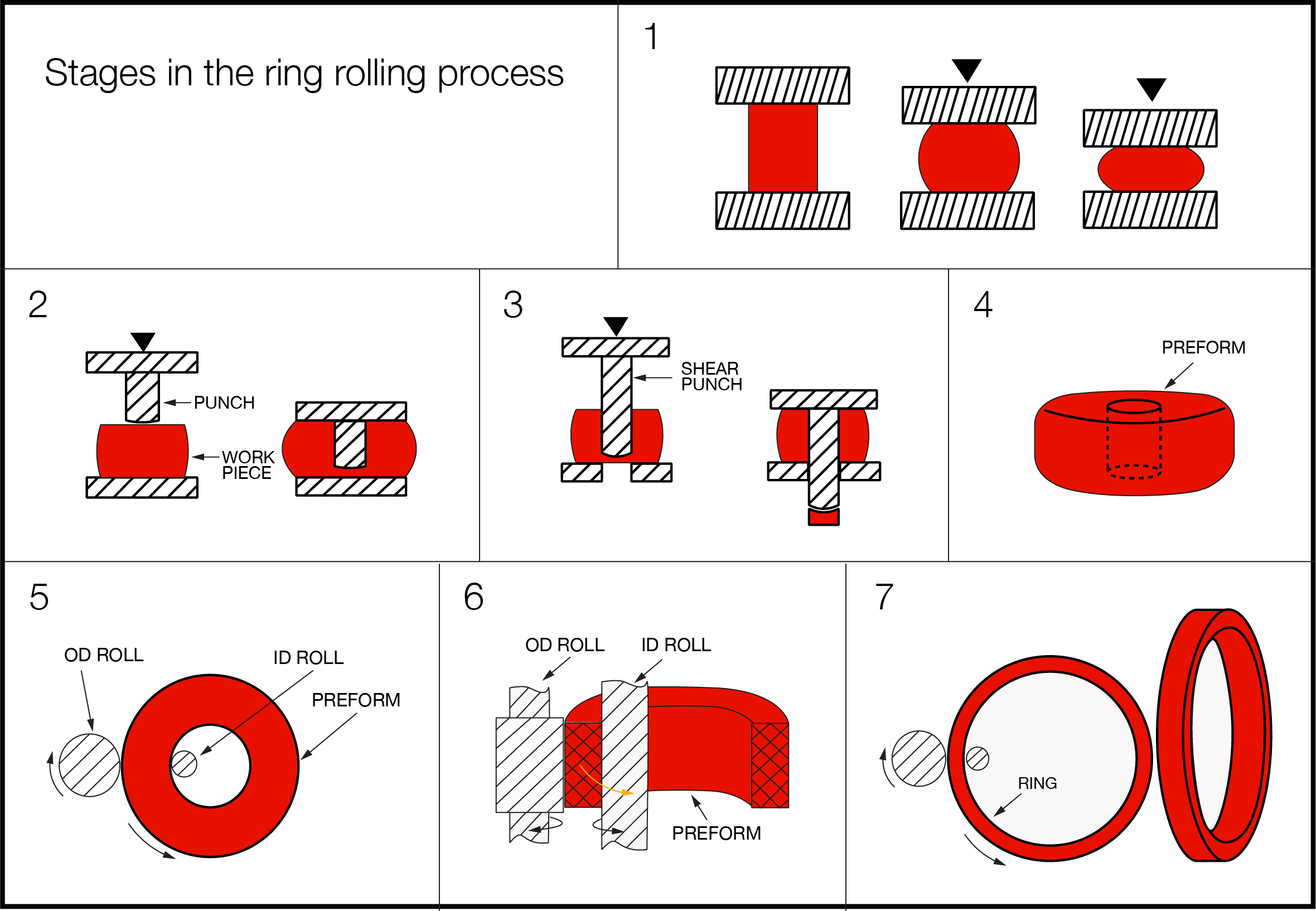

Ring rolling begins with a circular shape which has been forged using a compression die and pierced to make a hollow ring.

(Scroll down to learn more)

This piece is reheated and placed on a rolling mill and is rotated repeatedly. Applying pressure while the piece is in rotation reduces the cross-sectional area and expands the inner and outer diameters making a seamless rolled ring.

There are numerous ring rolling methods and equipment available that all yield a similar product. The average rolling mills are either horizontal or vertical and can produce a variety of ring sizes with outside diameters of up to 9.5 meters and weights of up to 65 tons. The shape of the rings ranges from flat, washer like shapes to big cylindrical shapes. Most commonly used is a rectangular, cross-section ring.

Download print version

The content of this page was curated for the distribution of industry related information from the Forging Industry Association and/or the American Foundry Society in reference to specific metallurgical processes.

Downloads

Company & Capabilities

Industries

Components

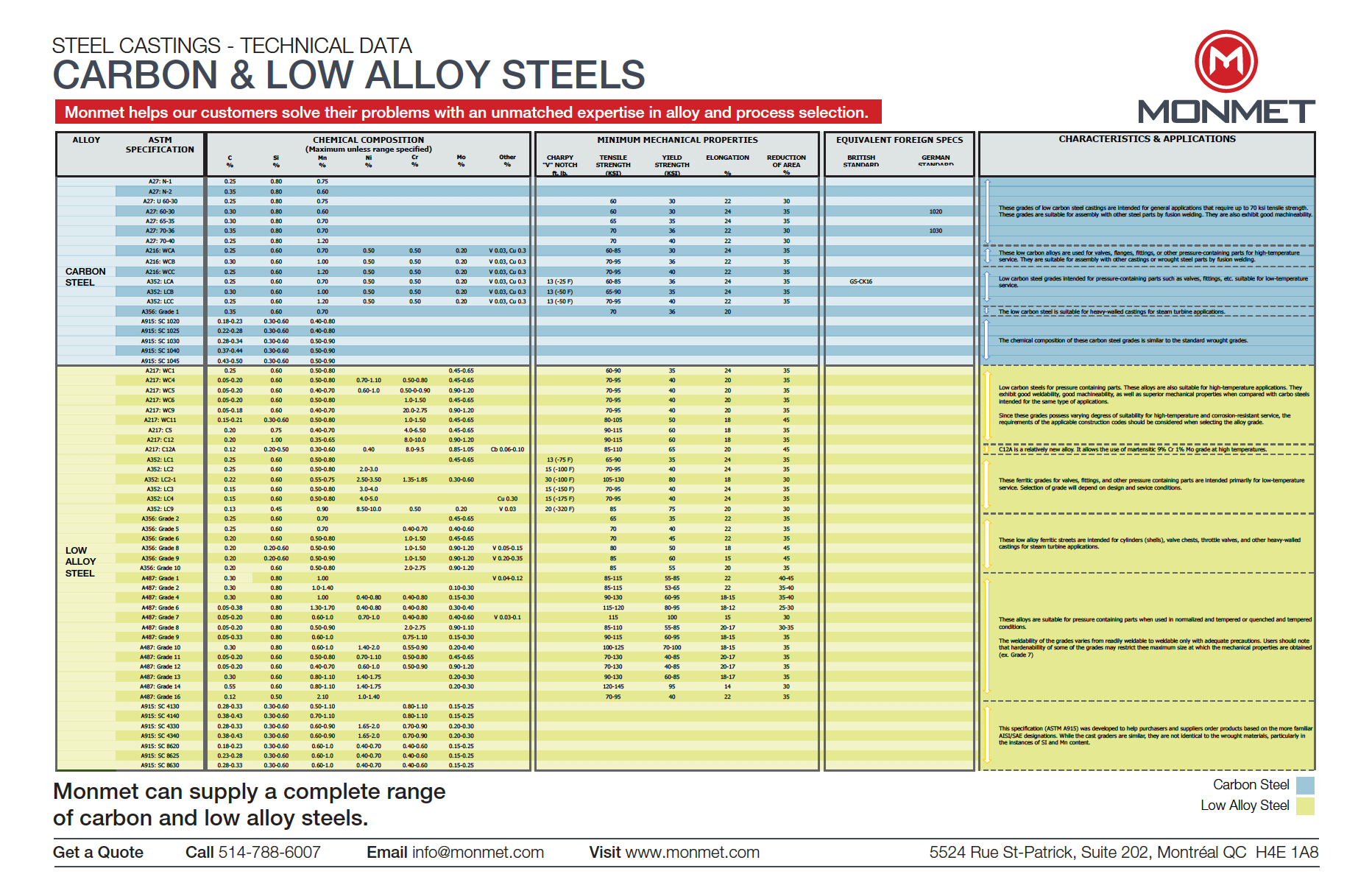

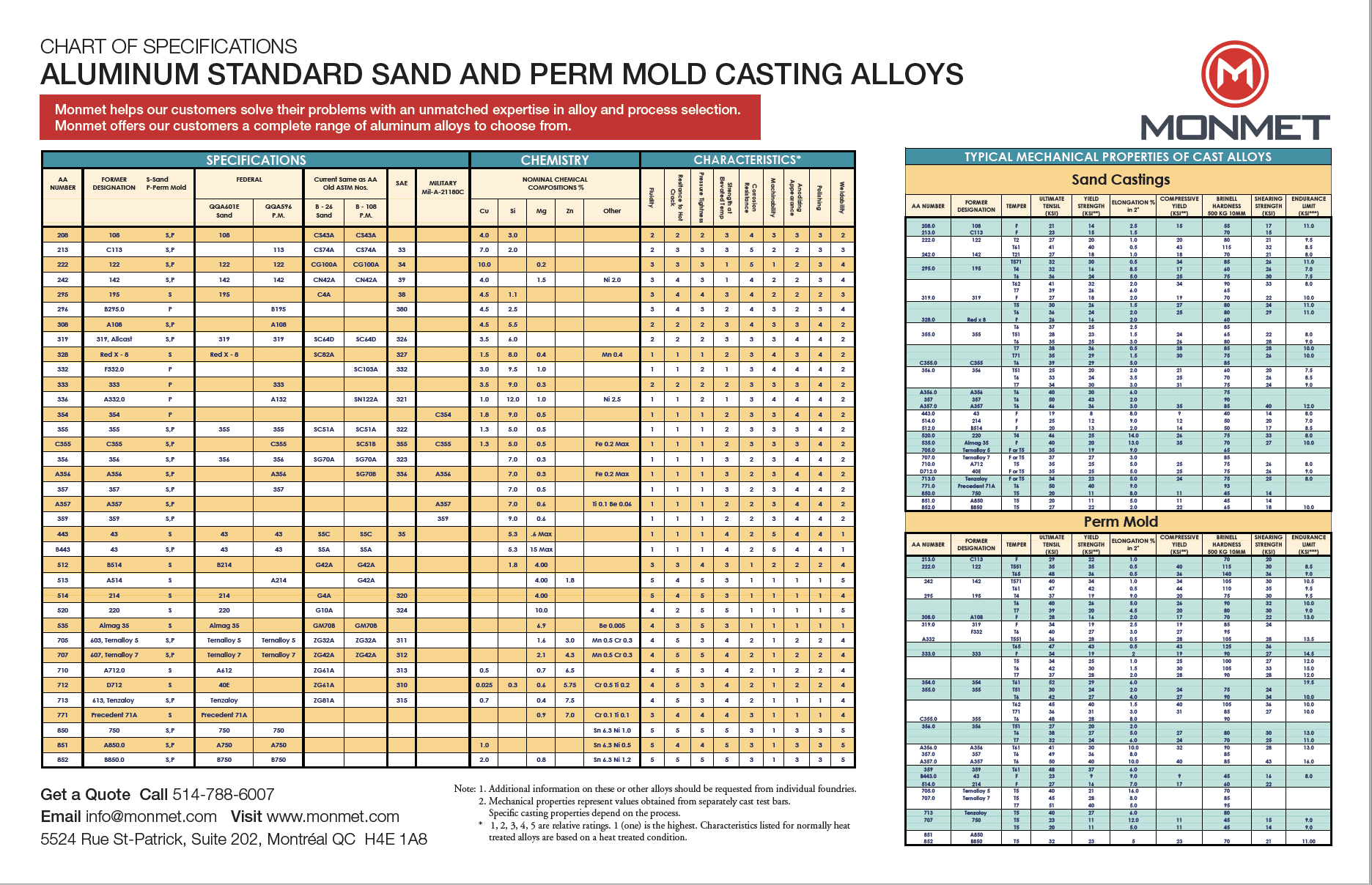

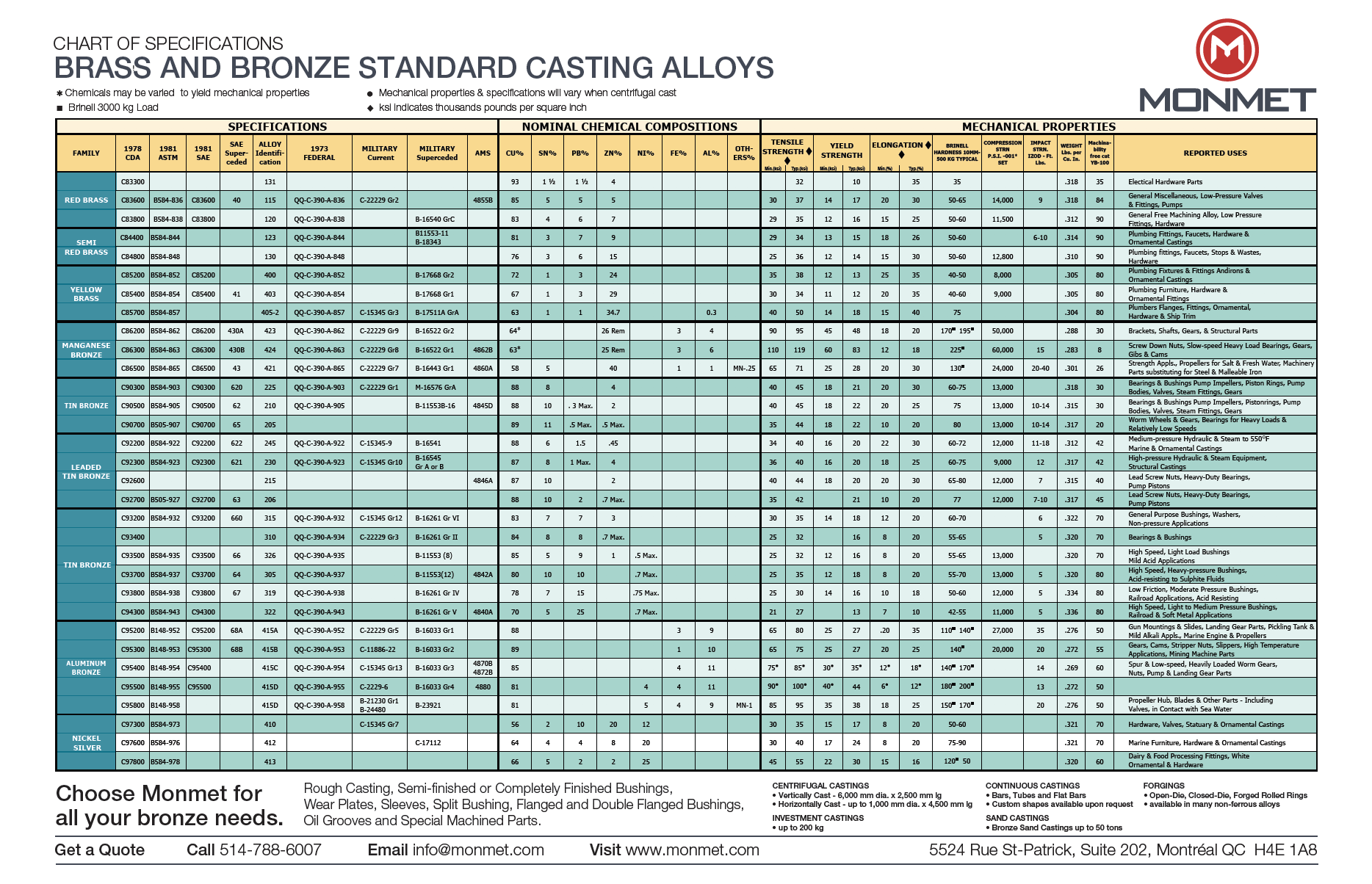

Technical Data

Learn Casting Processes

Sand Casting

Investment Casting

Centrifugal Casting

Continuous Casting

Learn Forging Processes

Open-Die Forging

Closed-Die Forging

Ring Rolling