Resources

Resources

resources

Closed die forging, also known as impression-die forging, is a process in which metal is molded by fully enclosing it between two dies.

(Scroll down to learn more)

The workpiece is placed on the bottom die. The top and bottom die are then pushed together to tightly press the piece inside the closed dies. The heated metal becomes malleable and is compressed repeatedly until the desired shape is achieved (Fig. 1). The maximum weight of a closed die forging is about 3,500 kilograms. More metal than needed is put into the press, leaving excess metal called flash. The flash serves as a crucial part of the process, creating increased resistance in the piece by building pressure and filling unfilled impressions.

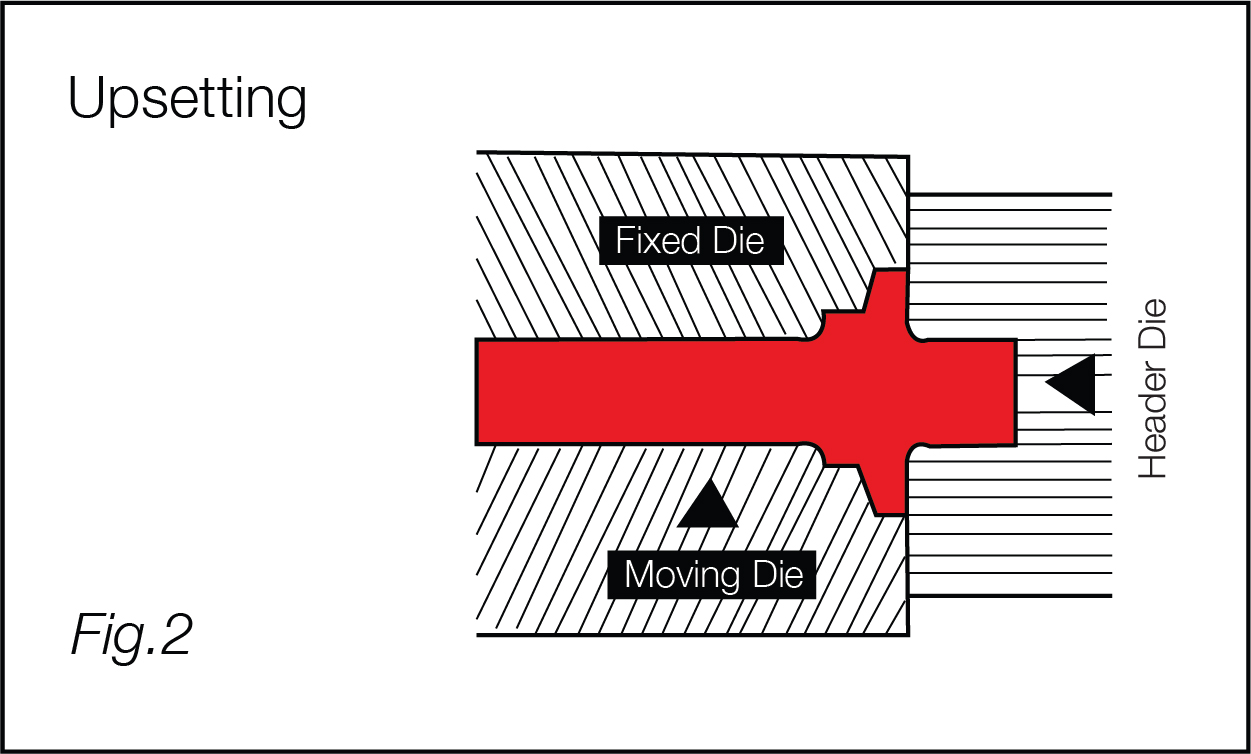

Upsetting as a forging process requires high speed crank presses- usually horizontal, but sometimes vertical- as well as hydraulic presses. A standard machine would have several split dies with many cavities. The process of upsetting has the metal between a fixed and a moving die while a horizontal ram repeatedly presses the piece to forge it (Fig 2). The dies open and close to allow movement between the cavities. When the dies close, the ram moves longitudinally along the piece, upsetting it into the cavity.

Download print version

The content of this page was curated for the distribution of industry related information from the Forging Industry Association and/or the American Foundry Society in reference to specific metallurgical processes.

Downloads

Company & Capabilities

Industries

Components

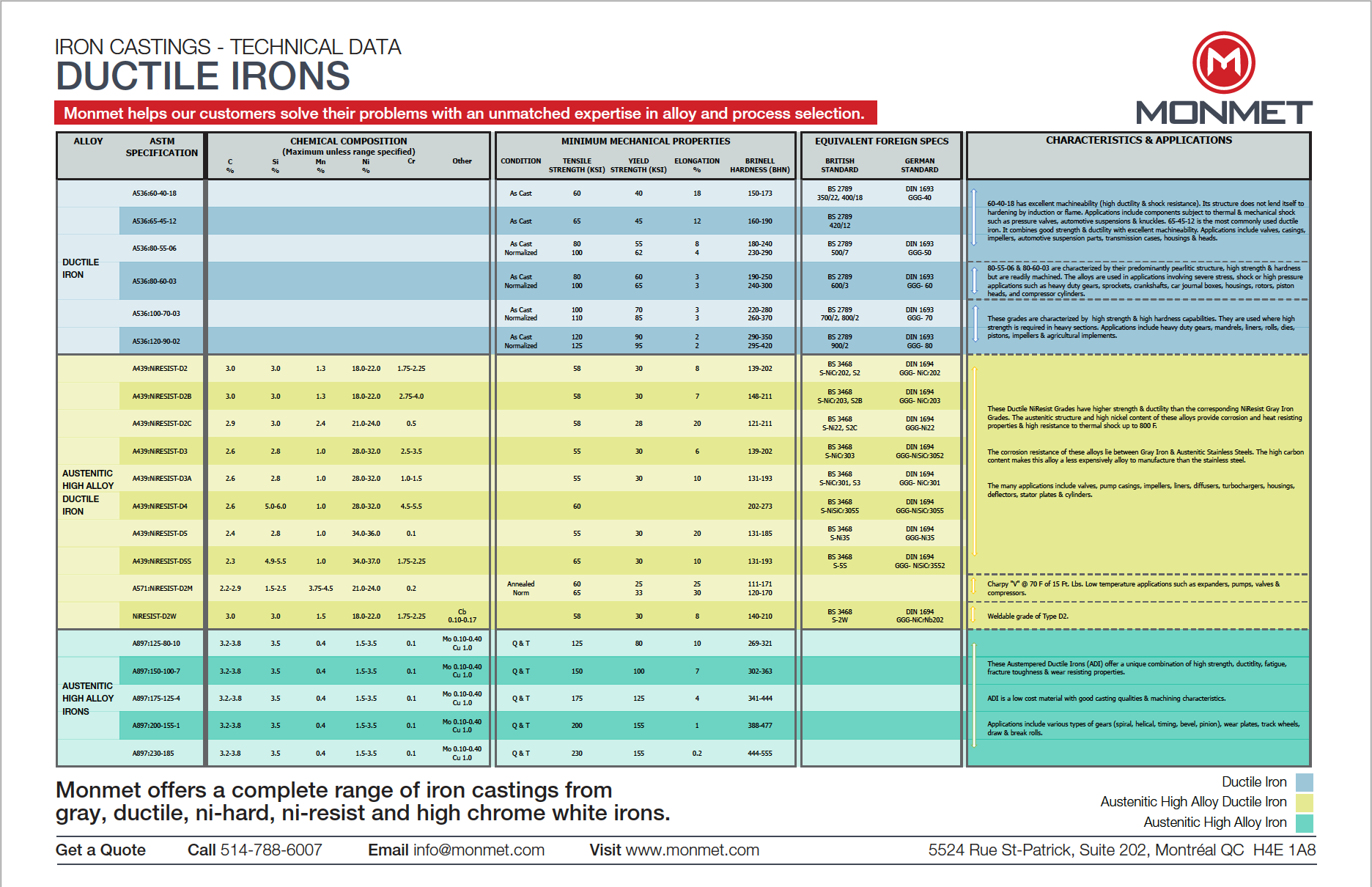

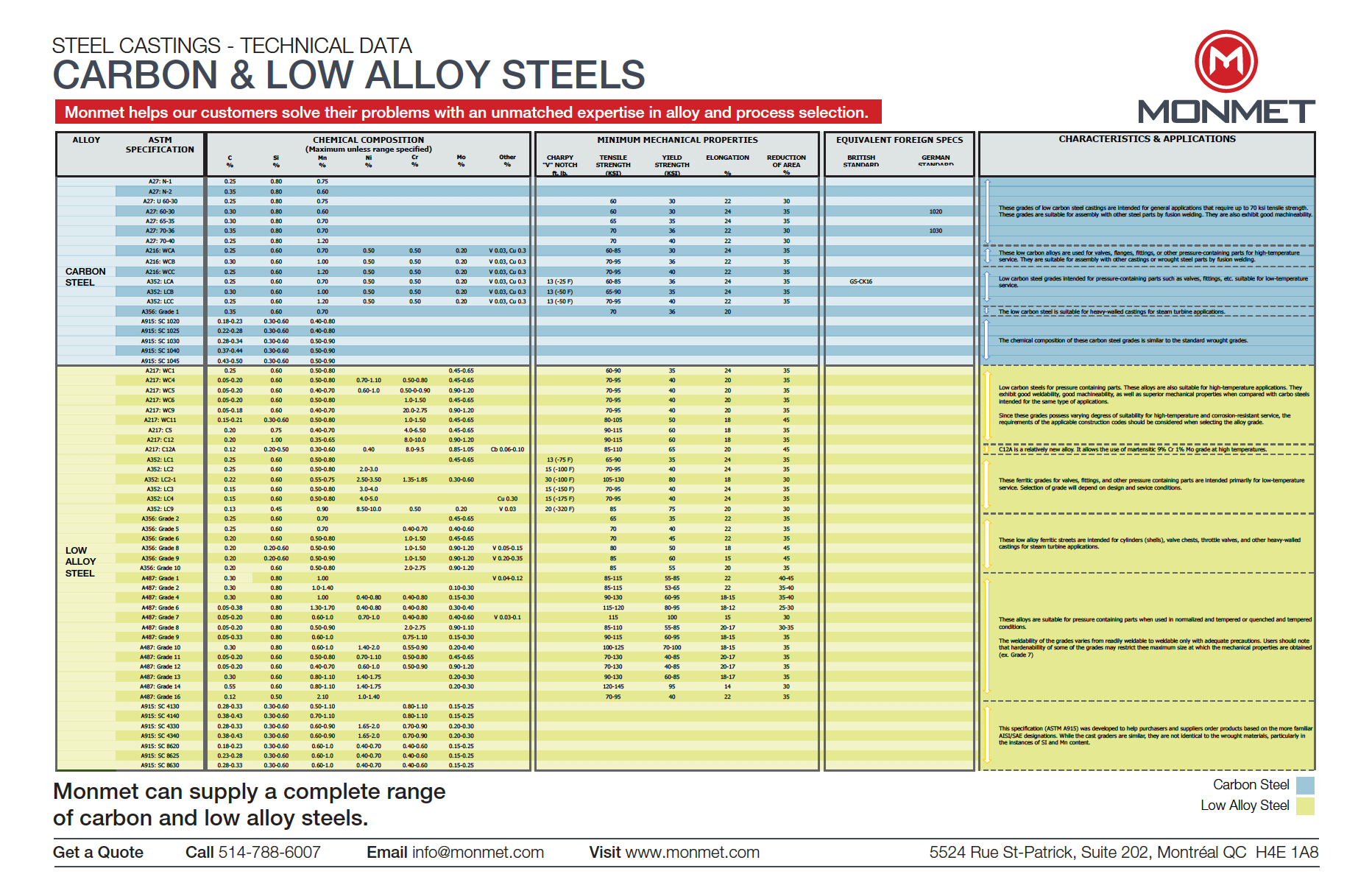

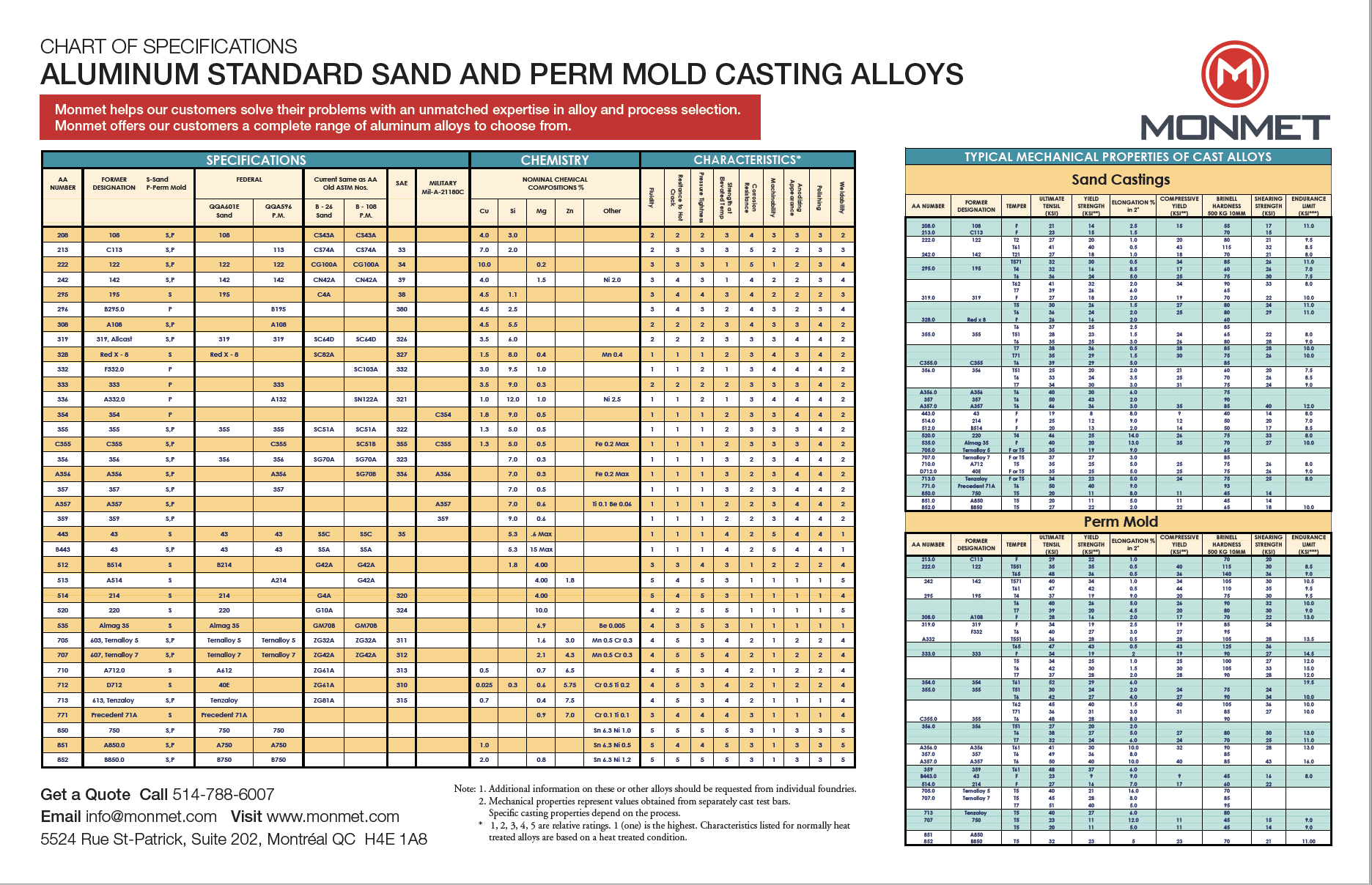

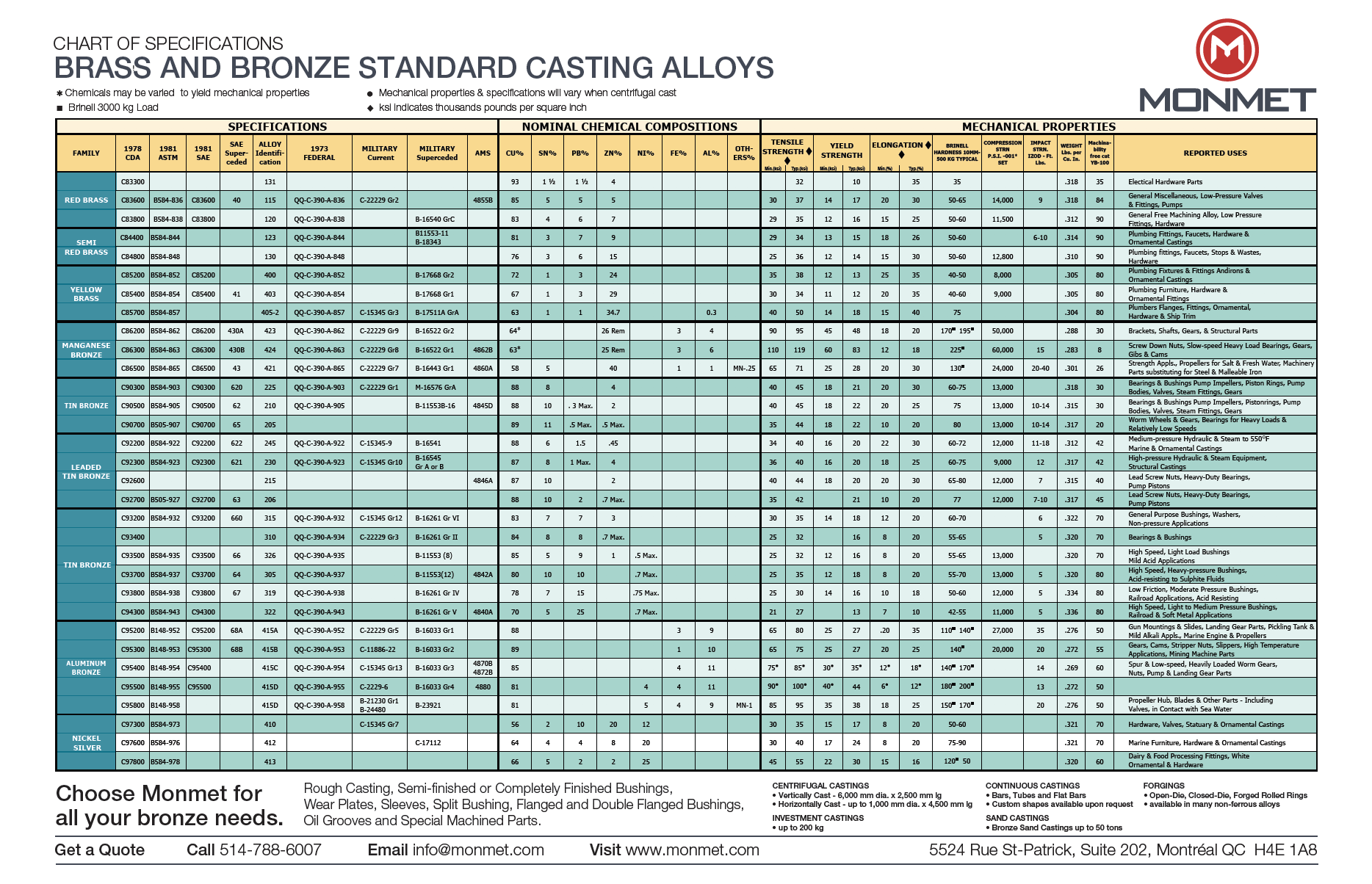

Technical Data

Learn Casting Processes

Sand Casting

Investment Casting

Centrifugal Casting

Continuous Casting

Learn Forging Processes

Open-Die Forging

Closed-Die Forging

Ring Rolling