Resources

Resources

resources

An open die forging is the modernized equivalent of a metalsmith working with a hammer and anvil. In this process, the piece is never fully enclosed but rather openly pressed between two dies.

(Scroll down to learn more)

The metal is heated above the recrystallization point and pressed between a top die, which is attached to a ram, and a bottom die attached to a hammer or press bed. This is repeated until the metal is properly forged into the desired shape. Most open die forgings are made on flat dies, but v-dies and round swagging dies are often used as well. The pieces usually consist of large, simple shapes like bars, disks, or hollows with weights of up to 160 tons.

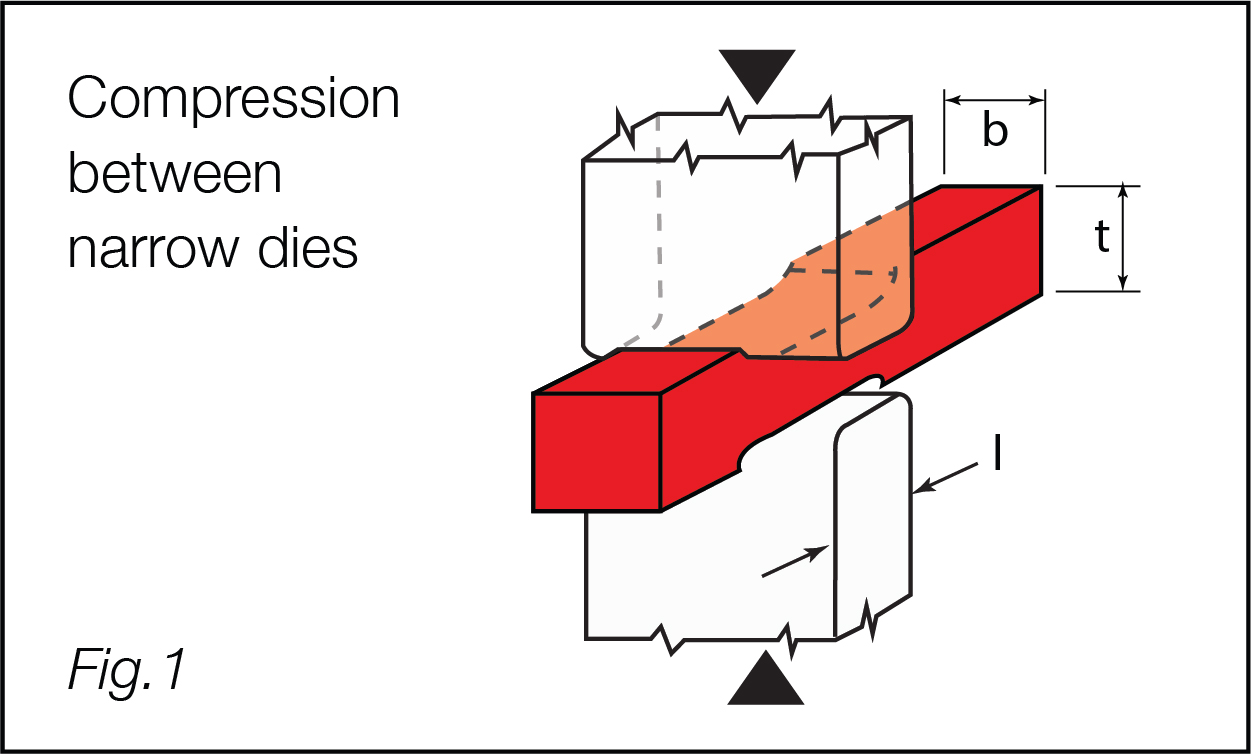

Upsetting is an open die forging process in which an oblong shape is compressed between two flat dies. The friction between the dies and the metal allows for the piece to remain formed, preventing unwanted lateral spreading. Compression between narrow dies (Fig. 1) creates a more elongated piece but is discontinuous as the piece needs to be repeatedly rotated as it moves in an axial direction. Making it continuous would require roll forging (Fig. 2). The larger the roll, the larger the lateral spread and the less elongated the piece will be. As a result of friction in the arc of contact smaller rolls can become more elongated. To diminish this lateral spread and create elongation, the piece would be compressed using specifically shaped rolls (Fig. 3).

Download print version

The content of this page was curated for the distribution of industry related information from the Forging Industry Association and/or the American Foundry Society in reference to specific metallurgical processes.

Downloads

Company & Capabilities

Industries

Components

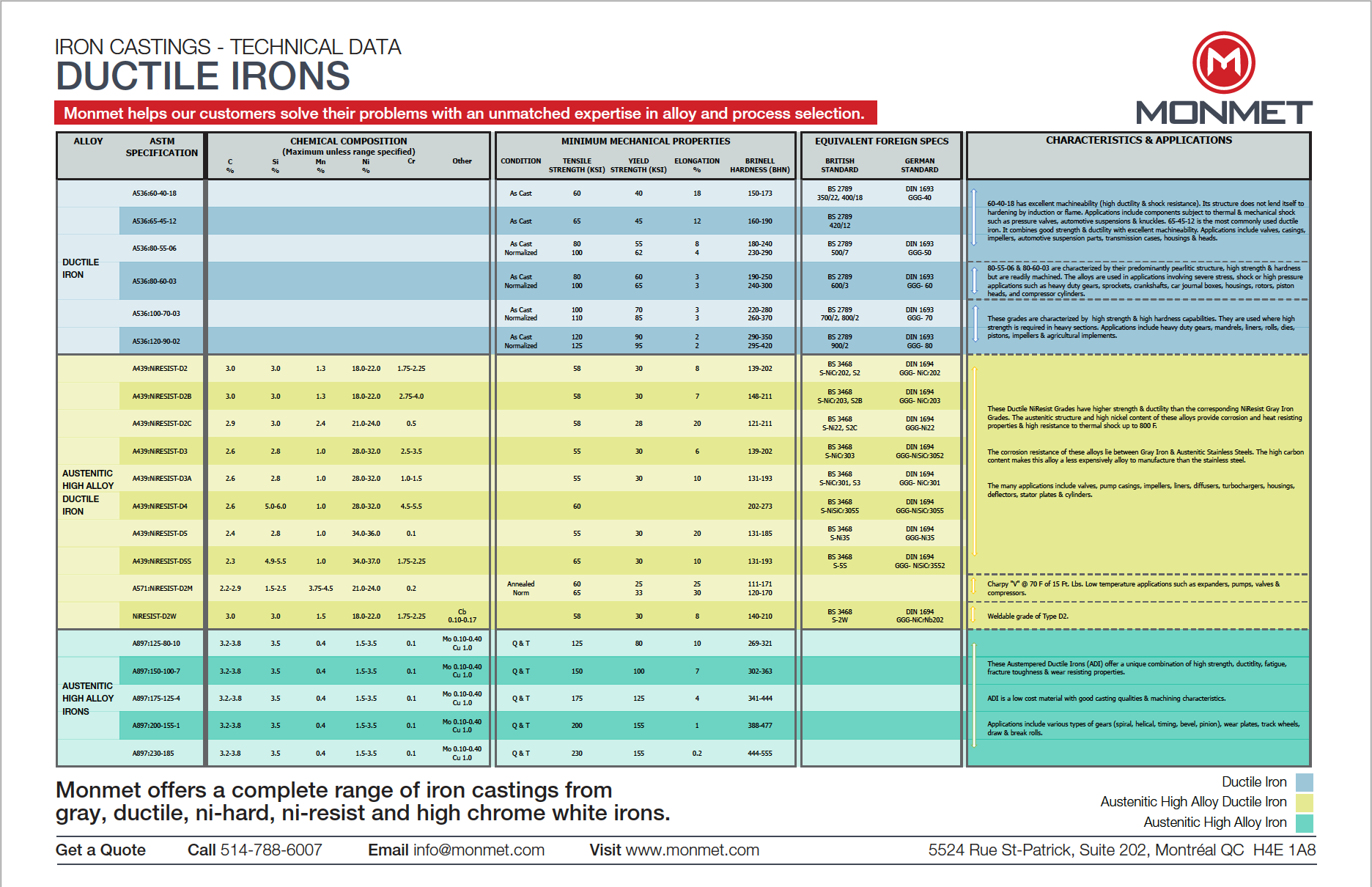

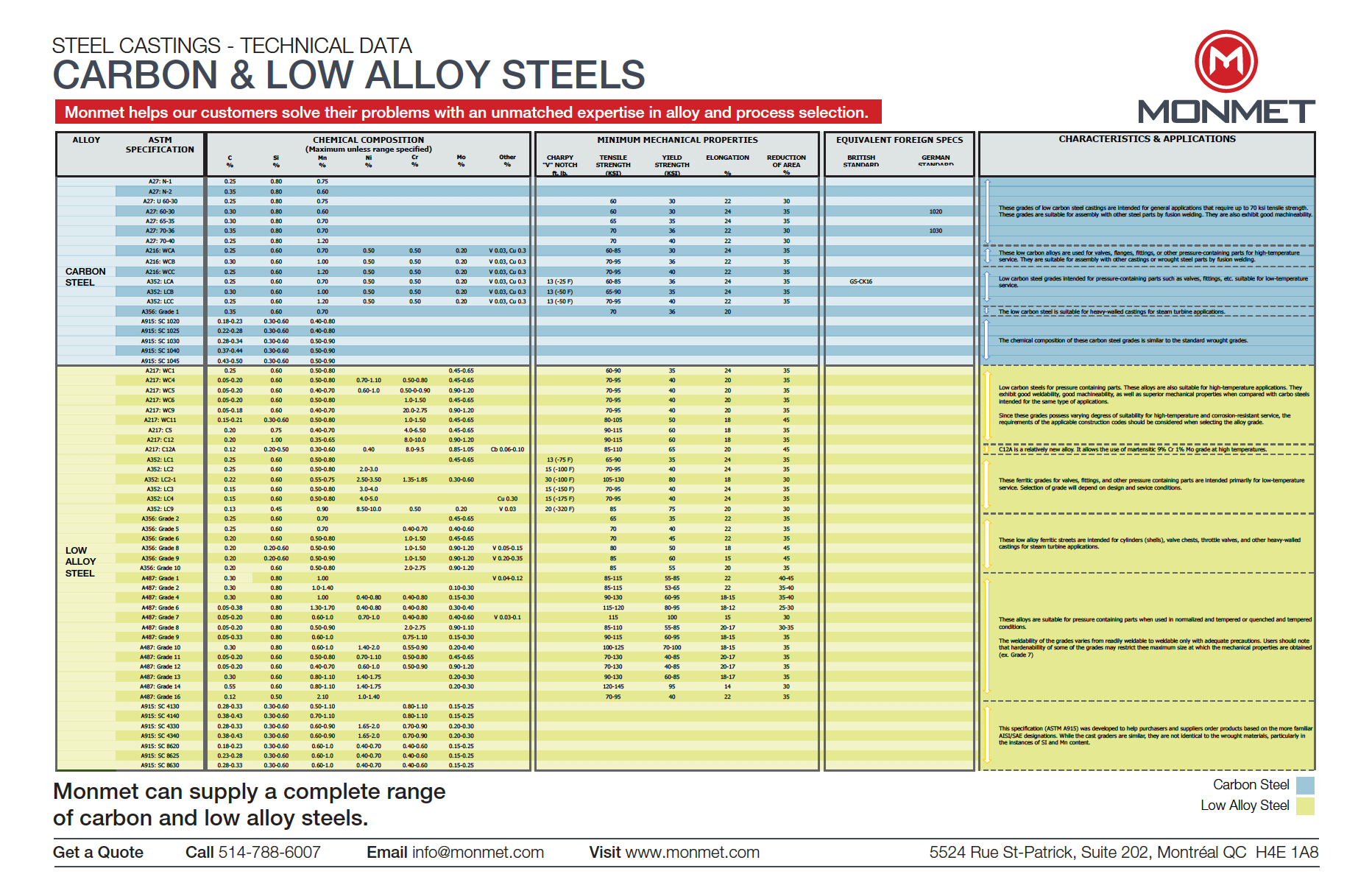

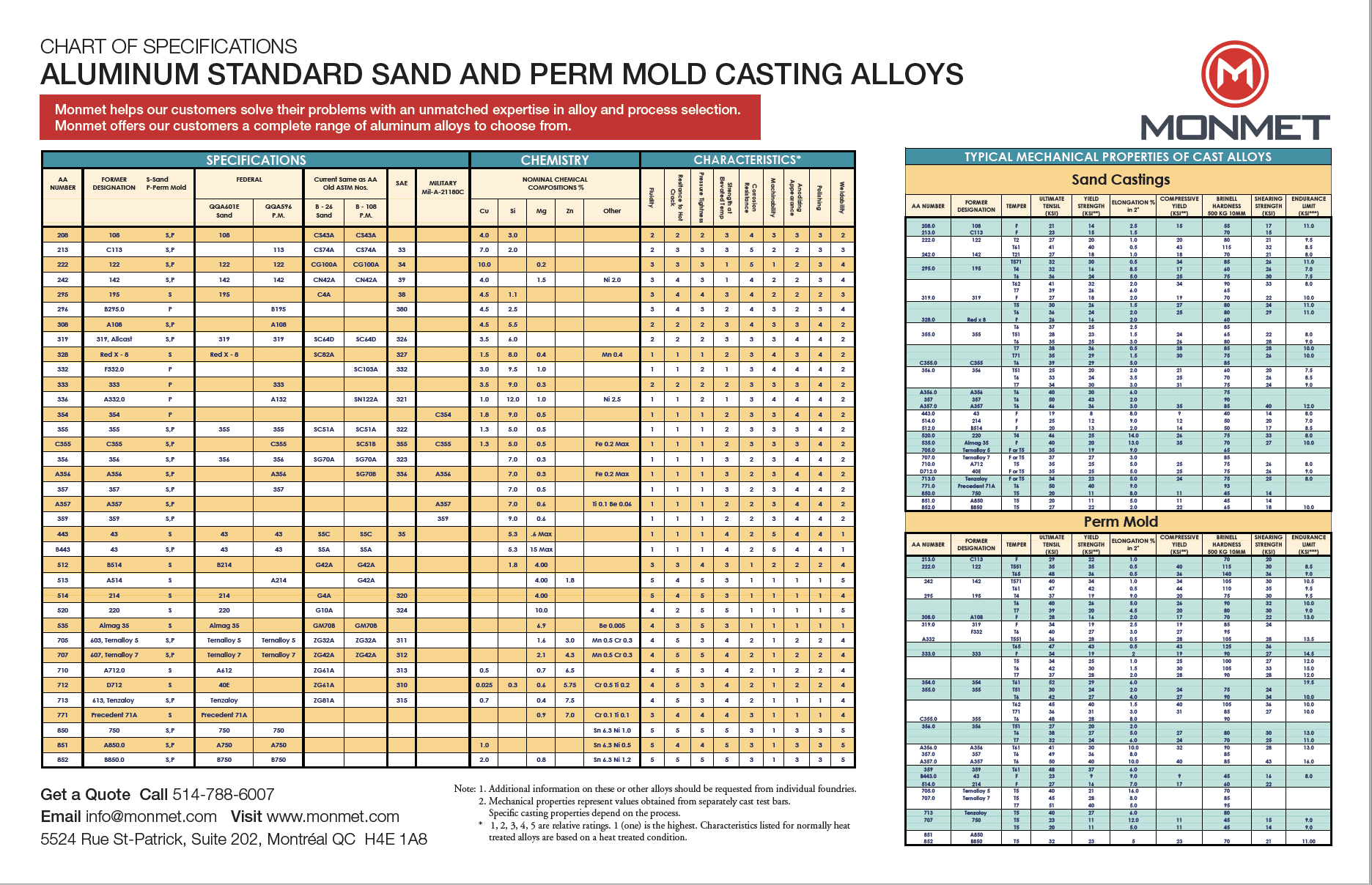

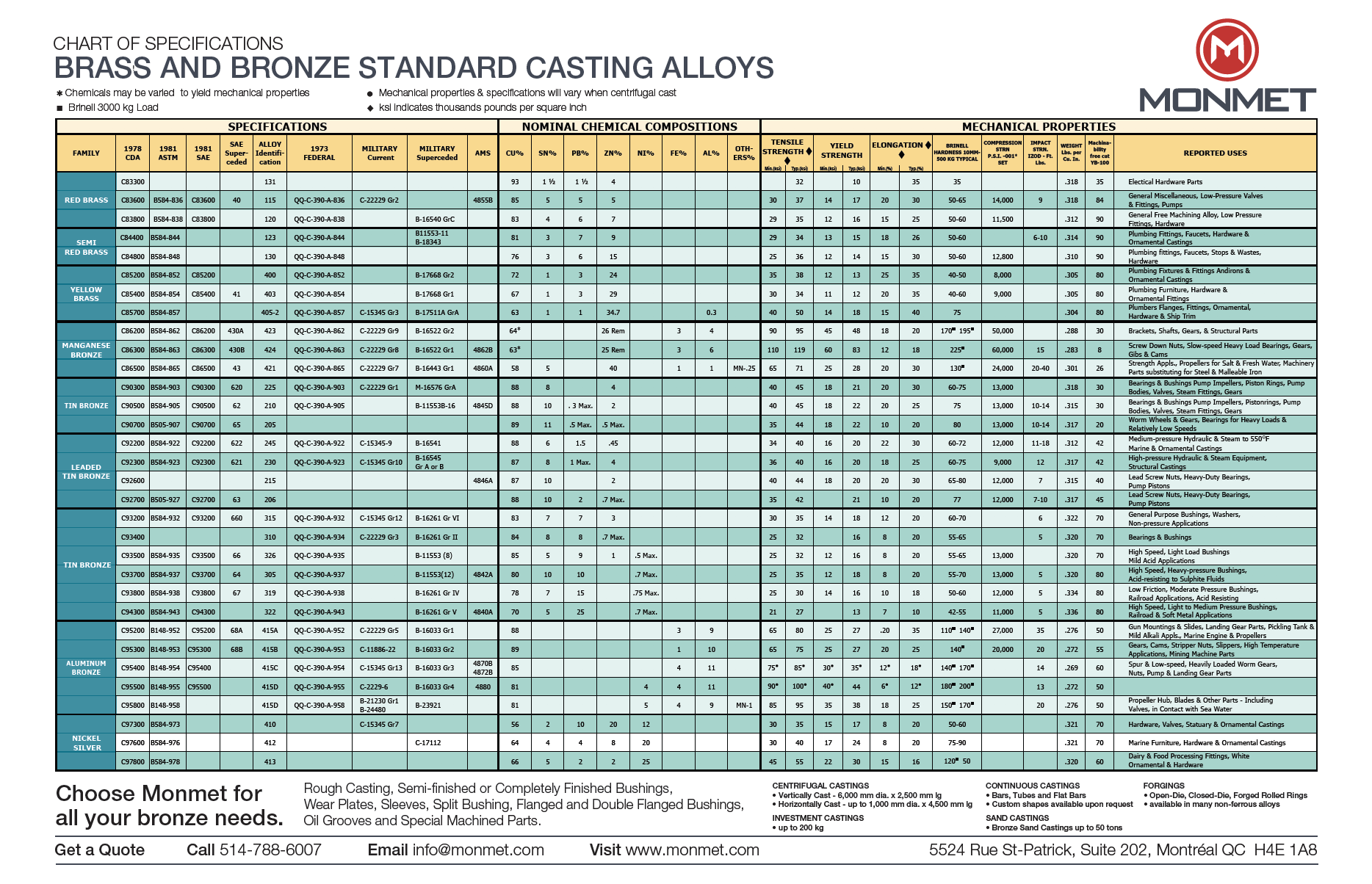

Technical Data

Learn Casting Processes

Sand Casting

Investment Casting

Centrifugal Casting

Continuous Casting

Learn Forging Processes

Open-Die Forging

Closed-Die Forging

Ring Rolling